State-of-the-Art Level 1 Inspection

Our inspection process uses all available OEM inspection data to determine the serviceability of your bearings. Bii’s team of maintenance professionals is comprised of the top bearing technicians and engineers in the industry. They use the OEM data to verify that every bearing meets or exceeds approval specifications, providing for their safe and reliable use in the application.

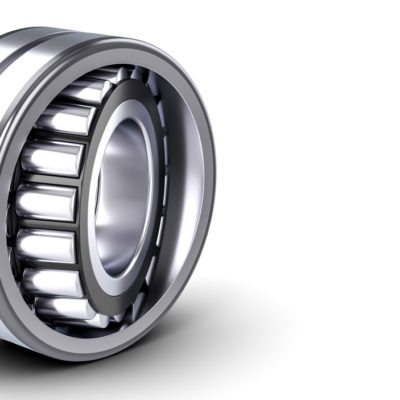

Complete Bearing Cleaning

Visual, dimensional, and functional inspection in accordance with OEM criteria

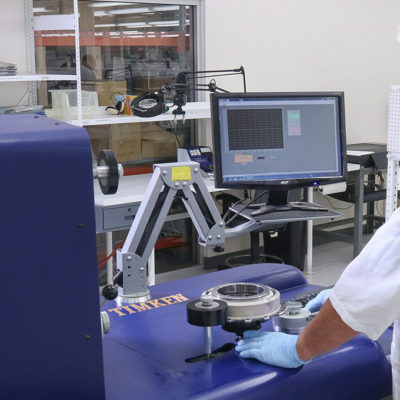

Dynamic analysis using Bearing Analyzer

Bii Dynamic Analyzer Technology

Bii’s maintenance technicians complete every inspection with the Bii Dynamic Analyzer technology to assure each bearing operates like new. Our efficient in-house processes allow for a prompt five-day turn-around for total inspection services. We are committed to further reducing the bearing inspection process time through ongoing Lean and Continuous Improvement Programs.

When ready for shipment, each bearing is cleaned and preserved in vacuum-sealed packaging complete with a FAA 8130-3 tag and a profile card containing the actual measurements of each main engine bearing.