The Process

Inner and outer raceways honed and super finished. Outside surfaces are visually and dimensionally inspected. New rolling elements are matched with bearing rings to meet OEM Specifications.

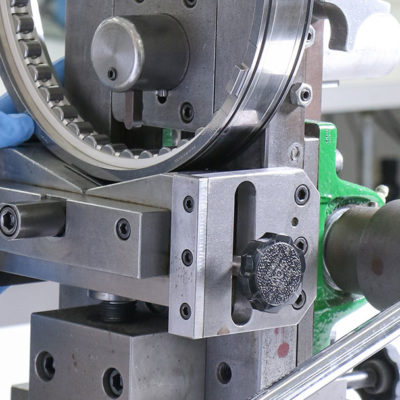

Step One: Raceway Honing

Step Two: Rolling Element Replacement

Step Three: Complete Inspection

Step Four: Assembly and Testing

Step Five: Final Inspection

Step Six: Shipment

The Cost Savings

We offer global carriers, engine overhaul facilities, ground power generation facilities, and military organizations significant cost savings and reduced inventory investment. When you use Bii for the inspection and reconditioning of your ball and roller bearings, you will enjoy the types of savings that come with an extended lifetime for your original bearings.