Inspecting Since 1955

Proven Quality Performance

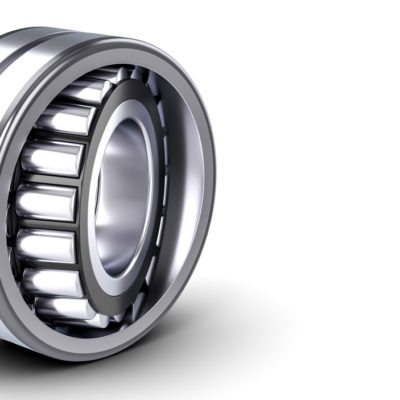

Our process pioneered the quality standards for bearing inspection and overhaul return service. Through studies performed by our parent company, Timken, and independent studies from NASA and Purdue University, we can firmly report that bearings can be returned to service with refurbishment.

Turnaround Times You Can Count On

We work closely with customers to establish response and turnaround time (TAT) that helps them meet their build schedules. With the proper paperwork and parts preparation, all bearing overhauls can be completed in 15 business days or better.

5 Business Day Inspection Process

15 Business Day Refurbishing Process

Servicing Manufacturers Across the Globe

Bii can inspect and refurbish any brand, anytime, with our in-house repair development program.

With 60 years of setting industry standards, we can make your bearings last.

- Bell

- Boeing

- GE

- Hamilton Sunstrand

- Honeywell

- Rolls Royce

- Sikorsky

- Pratt & Whitney

Extending Bearing Lifetimes

Our aerospace bearing reconditioning process returns your bearings to a like-new operational condition without sacrificing the quality, safety, or service life of your bearings. In fact, 80% of the bearings we receive are candidates for repair or overhaul. Based on bearing endurance data collected by NASA, approximately 92% of bearing sets that are available for refurbishing, result in a lifetime equaling or exceeding the predicted life of a new bearing.

Ready to find cost savings for your bearing repairs?